Industrial Printing

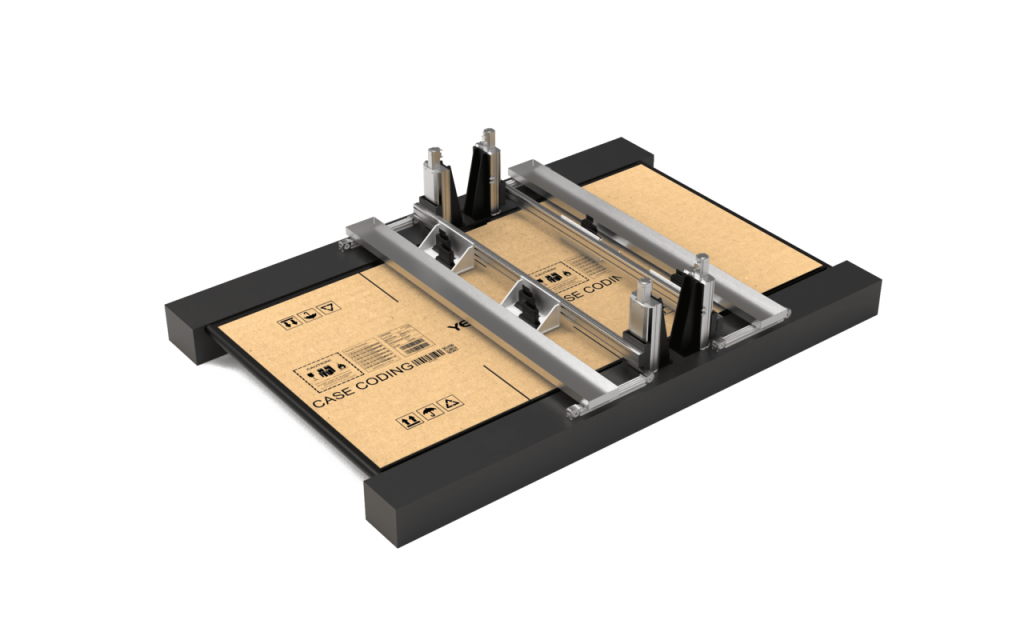

Large Format ONE PASS Custom Printing Bar Solution

Designed for Industrial Production:

Utilizes Single-pass piezoelectric printing technology to achieve ultra-wide format one-time output, greatly improving production efficiency.

Flexible Multi-Head Configuration:

Offers a variety of PIJ printhead models, supporting seamless stitching of multiple printheads, with unified management of printheads and ink supply systems.

Nozzle-Level Ink Recirculating:

Ensures continuous and stable printing performance, reduces maintenance frequency, and extends the uptime of printhead.

Stable Operation Around the Clock:

Supports 7×24 hour continuous operation, reliable performance, low maintenance cost, and easy integration into production lines.

Wide Material Compatibility:

Suitable for various substrates such as paper, film, cardboard, metal, and textiles.

Flexible Functional Expansion:

Can be configured with ink types, UV curing systems, and automation devices as needed to meet diverse production requirements.

High-efficiency and Stable Operation:

Optimized inkjet system design ensures continuous and stable printing, meeting the requirements of industrial production.

Large Format Sideward Printing Custom Solution

Ultra-Wide Format Printing:

Integrates 10 printheads, with a single print width up to 1080mm, meeting the efficient production needs of large-sized workpieces.

Intelligent Distance Detection:

Equipped with a high-precision distance sensing system, automatically adjusts the printhead position to ensure optimal printing height is maintained.

Long-throw Distance Printing Technology:

The throw distance can reach 30mm, suitable for more special shapes or uneven surfaces.

Nozzle-Level Ink Recirculating:

Achieves precise ink recirculating, significantly reducing maintenance frequency and extending the uptime of printhead.

Stable Adaptation to Harsh Environments:

Maintains stable output in harsh production environments such as dust and humidity fluctuations, ensuring production continuity.

Digital Ceramic Decal Printer

High-Temperature Resistant Special Ink:

Uses special ceramic UV ink, with high-temperature resistance up to 1200°C, suitable for ceramic firing processes.

Nozzle-Level Ink Recirculating:

Ensures stable ink flow, effectively prevents printhead clog, and improves printing efficiency and quality.

Multi-Channel Printhead Configuration:

Supports CMYK full-color printing, and can be expanded with special colors, varnish, and white base printing to achieve rich colors and special effects.

Efficient and Stable Operation:

Optimized inkjet system design ensures continuous and stable printing, meeting the needs of industrial production.

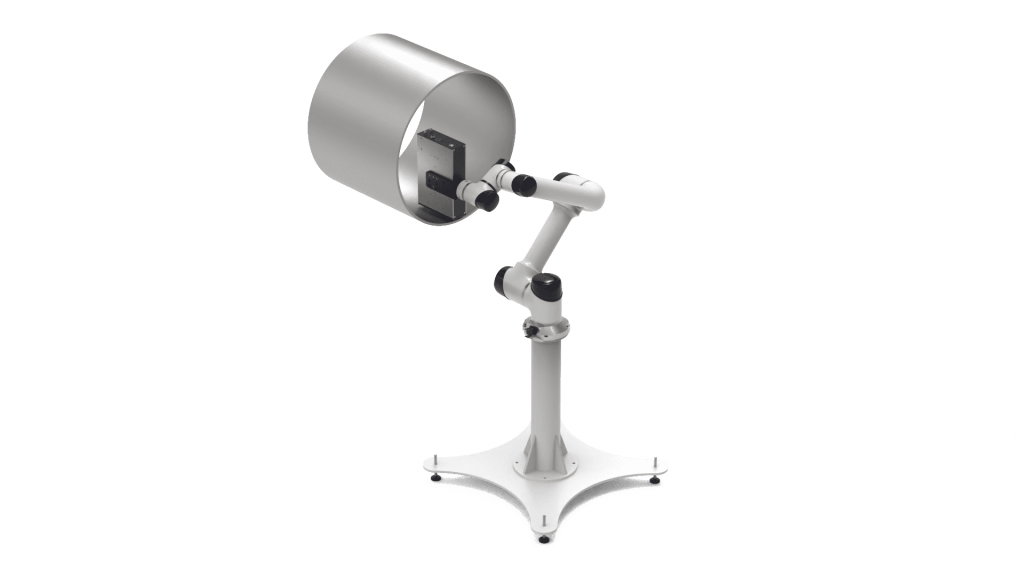

Industrial Printing Robot --- Steel Pipe Inner Wall Coding Solution

Innovative Ink RecirculatingSystem:

Achieves nozzle-level recirculating without the influence of liquid level changes, ensuring stable ink and continuously stable printing.

Robotic Arm 360° Rotation Printing:

Supports full-range rotation of the robotic arm to meet the complex surface coding needs of the inner wall of steel pipes.

Industrial Integrated Design:

Integrates printing, pre-curing, post-curing, and ink supply systems for unified management, simplifying the deployment process.

Intelligent Software Support:

Powerful software functions, easily achieve seamless connection with MES, ERP systems, and assist in intelligent production management.

Adaptation to Complex Industrial Environments:

The equipment is stable and reliable, capable of performing in industrial sites with dustyand complex environments, ensuring productivity