Introduction:

Piezoelectric inkjet printers, commonly known as high-resolution UV inkjet printers, have gained increasing popularity in coding and marking applications across various industries due to their high-quality and high-resolution printing performance. Compared with traditional carton labeling technology, this type of printer leveraging piezoelectric technology offers unique advantages. This article will discuss the merits of piezoelectric inkjet printers in carton coding and marking applications and look into their future development.

Advantages of Piezoelectric Inkjet Printers in Carton Coding and Marking:

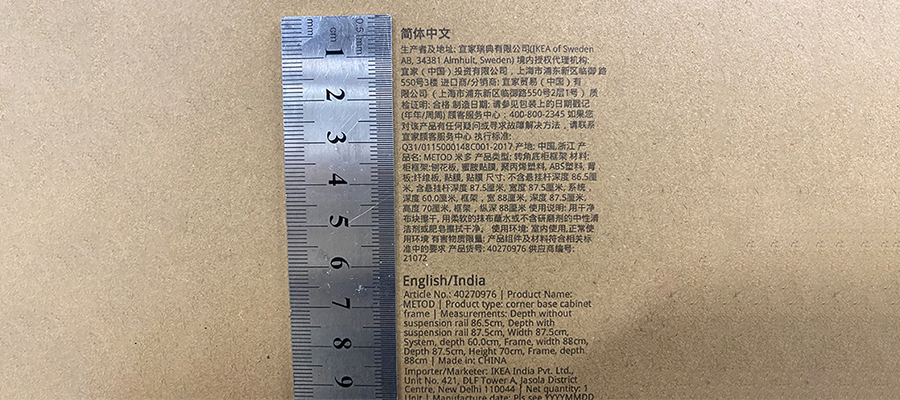

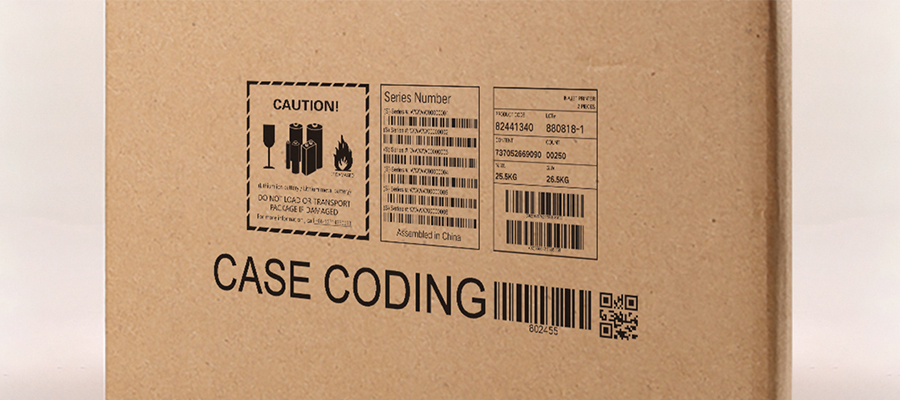

High-Definition,Large-Format Customized Printing: Piezoelectric inkjet printers enable high-resolution printing, ensuring the readability and accuracy of coding and marking applications. Compared with traditional carton labeling technology, they offer flexible, customized marking on large formats.

High Printing Speed: Piezoelectric inkjet printers boast fast printing capabilities, helping improve production efficiency and reduce downtime. Compared with traditional carton labeling technology, they can adapt to higher production line speeds.

Lower Consumable Costs: Compared with labeling technology, piezoelectric inkjet printers feature lower costs for ink consumables. Meanwhile, advancements in ink technology have significantly alleviated the issue of limited ink options.

Eco-Friendly Consumables: Piezoelectric technology enables precise ink droplet jetting, minimizing ink waste and reducing environmental impact. Piezoelectric inkjet printers help enterprises cut resource waste and lower their carbon footprint.

The Future Development of Piezoelectric Inkjet Printers in Carton Coding and Marking:

With continuous technological advancements, piezoelectric printers have steadily improved in stability, ink selection range, and cost reduction, while their application limitations have gradually diminished. Manufacturers and research institutions in the inkjet printing industry have also been optimizing piezoelectric inkjet technology through innovation and improvement, expanding its applications in the coding and marking sector.

As market demands and environmental requirements continue to rise, piezoelectric inkjet printers are also striving to enhance their eco-friendliness to minimize environmental impact. Additionally, with the development of smart manufacturing and Industry 4.0, these printers will integrate with other advanced technologies to achieve more efficient and intelligent production processes.

In summary, piezoelectric inkjet printers offer unique advantages in carton coding and marking applications, including high-definition, large-format customized printing, fast printing speeds, lower consumable costs, and eco-friendliness. Looking ahead, with continuous advancements in technology and equipment, their applications in the carton coding and marking industry will become more widespread, making them a competitive technical choice.